Used for drilling, chamfering, tapping and milling of plate/structure parts. It is mainly used for high-efficiency drilling processing of flanges, discs, rings, plates and other workpieces whose thickness is within the effective range. Drilling through holes and blind holes can be realized on single material parts and composite materials. The machining process of the machine tool is digitally controlled, and the operation is very convenient. It can realize automation, high precision, multiple varieties and mass production.

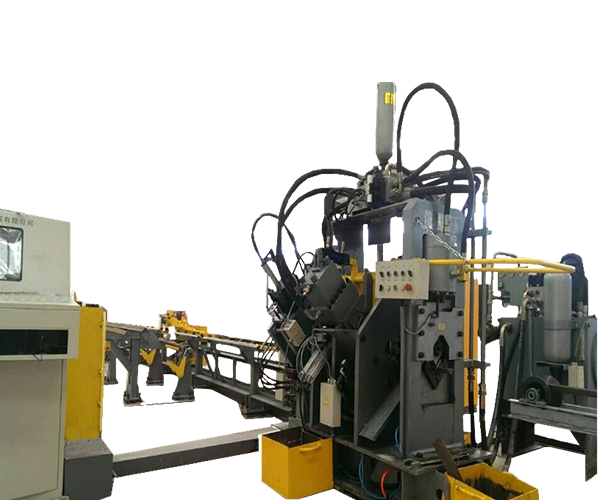

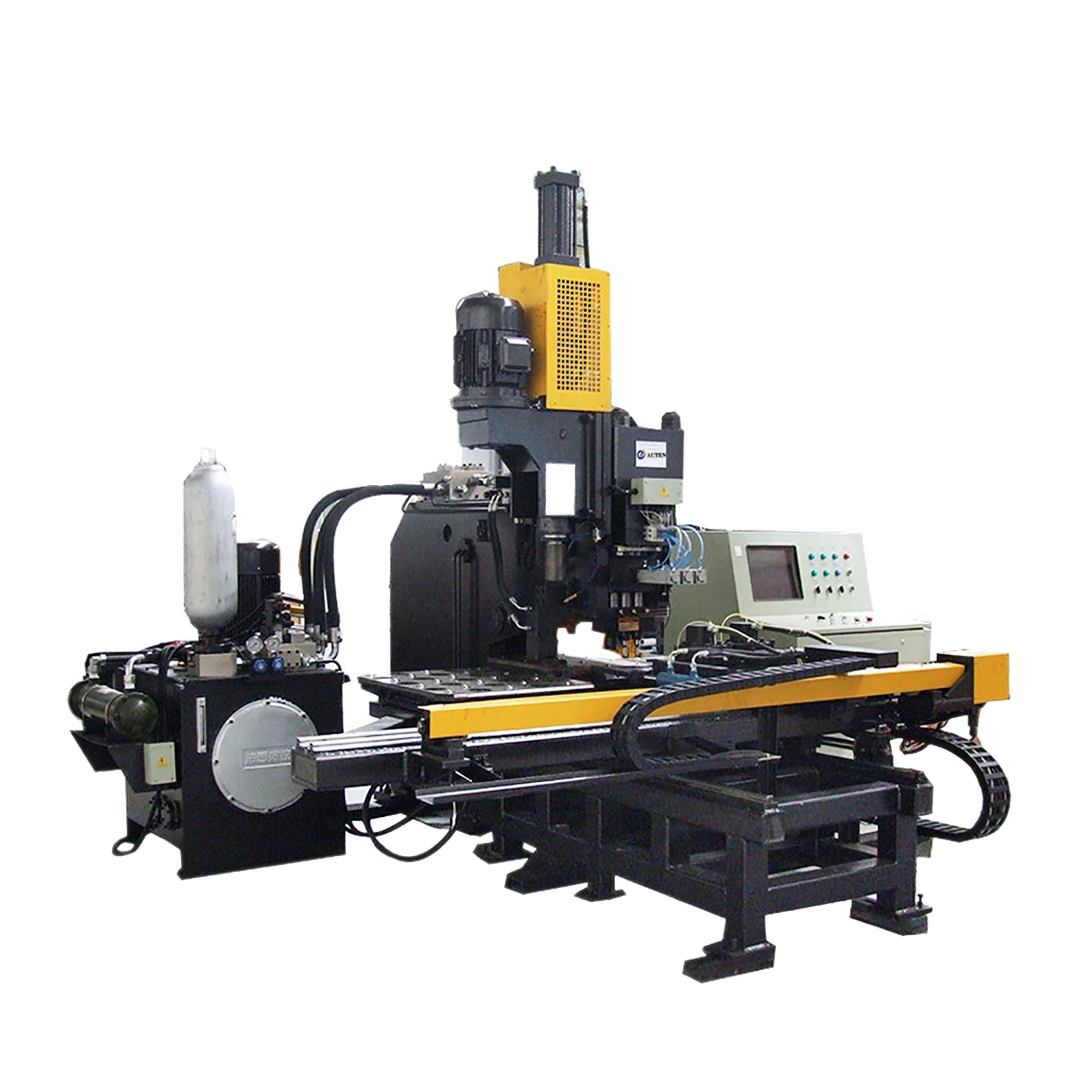

High Speed CNC Plate Drilling and Milling Machine Model PHD2525

Application:

Used for drilling, chamfering, tapping and milling of plate/structure parts.

It is mainly used for high-efficiency drilling processing of flanges, discs, rings, plates and other workpieces whose thickness is within the effective range. Drilling through holes and blind holes can be realized on single material parts and composite materials. The machining process of the machine tool is digitally controlled, and the operation is very convenient. It can realize automation, high precision, multiple varieties and mass production.

Machine structure:

The machine bed is cast, mainly composed of worktable, movable gantry, movable sliding saddle, drilling and milling power head, automatic lubrication device, protective device, circulating cooling device, digital control system, electrical system, etc. Rolling hard rail pair support and guidance, precision lead screw pair drive, the machine tool has high positioning accuracy and repeat positioning accuracy.

Workpiece size | LxW | 2500x2500 mm |

Workbench | T-slot width | 28mm |

Drilling power head | Qty. | 1 |

Spindle taper | BT50 | |

Max.drilling diamter | Φ100 mm (Carbide core bit) | |

Φ80 mm (U drill) | ||

Max.thickness | ≤300 mm | |

Max.tapping diameter | M30 mm | |

Spindle speed | 30~3000 r/min | |

Servo spindle motor power | 30kW | |

Distance from the lower end of the spindle to the worktable | 200-600mm | |

Lateral movement of power head (X axis) | Max.horizontal stroke | 2500 mm |

Lateral movement speed | 0~8 m/min | |

Servo motor power for lateral movement/torque | 4.5kW/25Nm | |

Gantry longitudinal movement (Y axis) | Max. feed stroke | 2500 mm |

Feed moving speed | 0~8 m/min | |

Feed servo motor power/torque | 2x4.5 kW/25Nm | |

Vertical ram feed motion (Z axis) | Max. stroke | 600 mm |

Moving speed | 0~5 m/min | |

Servo motor power/torque | 4.5kW/25Nm | |

Three-axis positioning accuracy | X/Y | ≤0.05mm/1000mm |

Three-axis repeat positioning accuracy | X/Y | ≤0.03mm/1000mm |