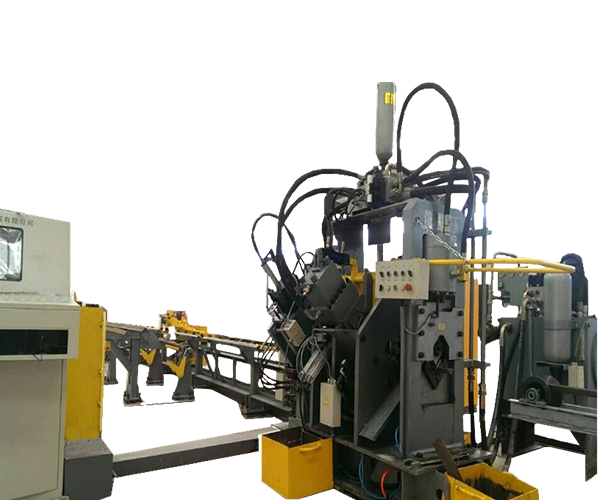

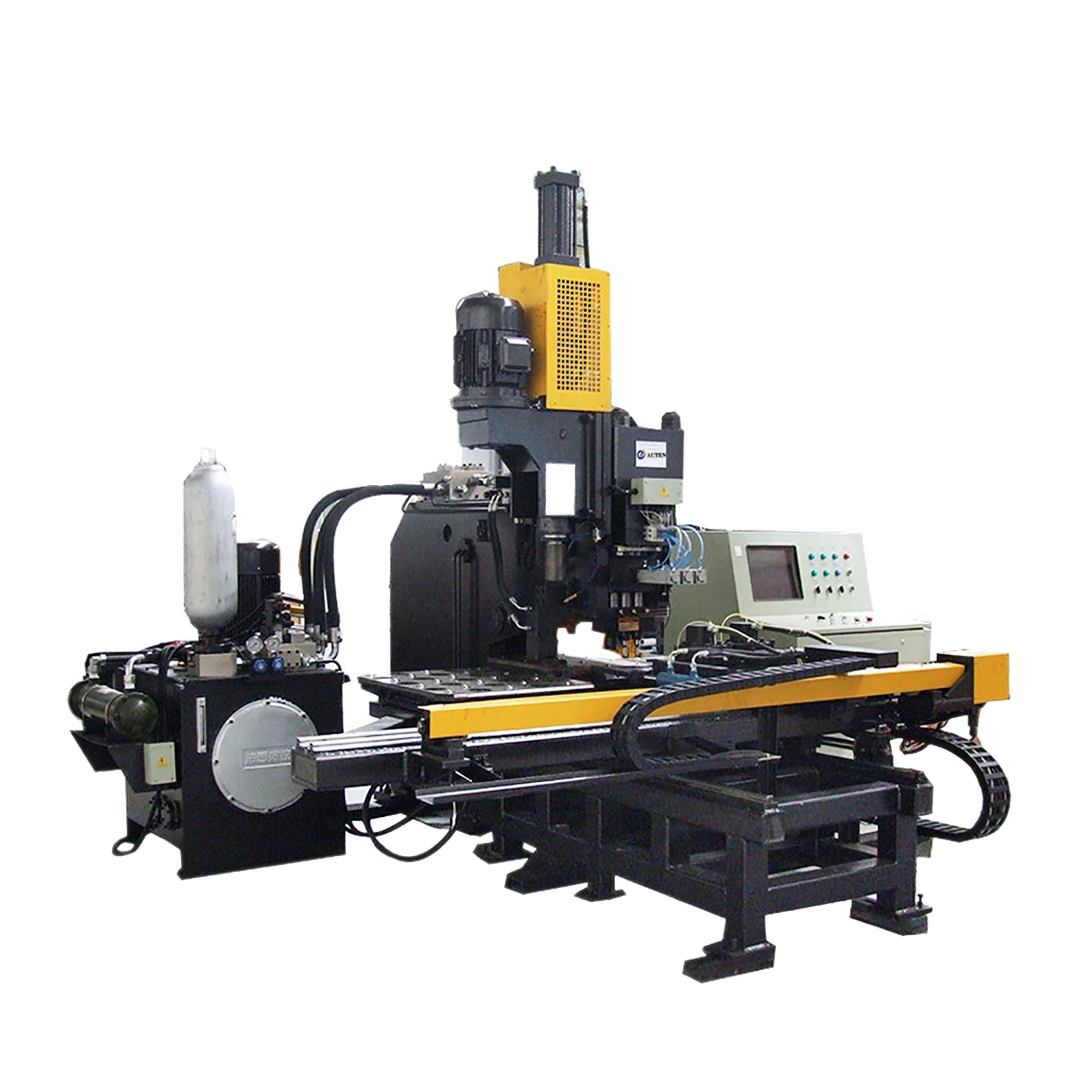

Used for punching, marking and drilling of steel plates in the field of steel tower. It is also used to punch, drill and mark of metal plates of other industries.

Hydraulic CNC Plate Punching and Marking Machine for Metal Plates

1. The machine-frame is made by C-type plate welding, with good rigidity and big handling space. The machine sets three die-stations (among them, one is the marking die-station), automatic switching die-stations. Clamping system can adapt to different work piece, with zero baffles as datum mark, and work piece supported by rolling-ball working table. Axis X & Y action should be controlled by servo motor and ball-screw driving, and double-axis CNC system controls the position of punching, so as to make the whole machining process automatically; operator may input the sizes of work piece to computer for repeated calling program in the future.

2. Adopt CNC technology, servo motor in feeding, with high efficiency, stable work piece precision.

3. Important functional components adopt modular assembly, easy to repair it.

4. Carry out punching, marking and drilling on the one plate.

5. Drilling unit has the functions including rapid falling, slow work-feeding and quick feeding back to improve working efficiency.

6. Easy programming, may input the diameter of holes, position and the quantity of work piece to computer, and also may use the program generated by lofting software, or adopt direct conversion CAD/CAM.

7. With function of self-diagnosis for failures.

8. Lighten the working strength of workers.

Model | BNC100 | BNCZ100 | ||

Max size of work piece L×W(mm) | 1500×800 | |||

Max. punching diameter (mm) | Φ26 | |||

Max. drilling diameter (mm) | / | Φ50 | ||

Plate thickness (mm) | Punching | 5~25 (Q235) | ||

Drilling | 40 | |||

Punching force (kN) | 1000 | |||

Marking force (kN) | 800 | |||

Min. distance between hole and plate edge (mm) | Punching | 25 | ||

Drilling | Depends on hole diameter | |||

Character size(mm) | 14×10×19 | |||

No. of character | 12 | |||

Die-stations | 3 | 4 | ||

Feeding speed of drilling(mm/min) | / | 25~280 | ||

Stroke of drilling spindle(mm) | / | 180 | ||

Rotation speed of drilling spindle(r/min) | / | 120~560 | ||

Precision | Accordance with GB2694 | |||

Programming mode | Input by keyboard, RS232 interface and USB interface | |||

Overall dimensions L×W×H (mm) | 3200×3000×1900 | 3200×3000×2600 | ||

Machine weight (kg) | About 5400 | About 5800 | ||