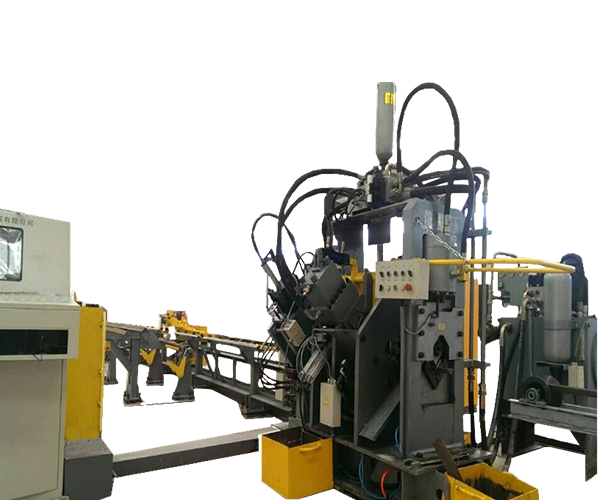

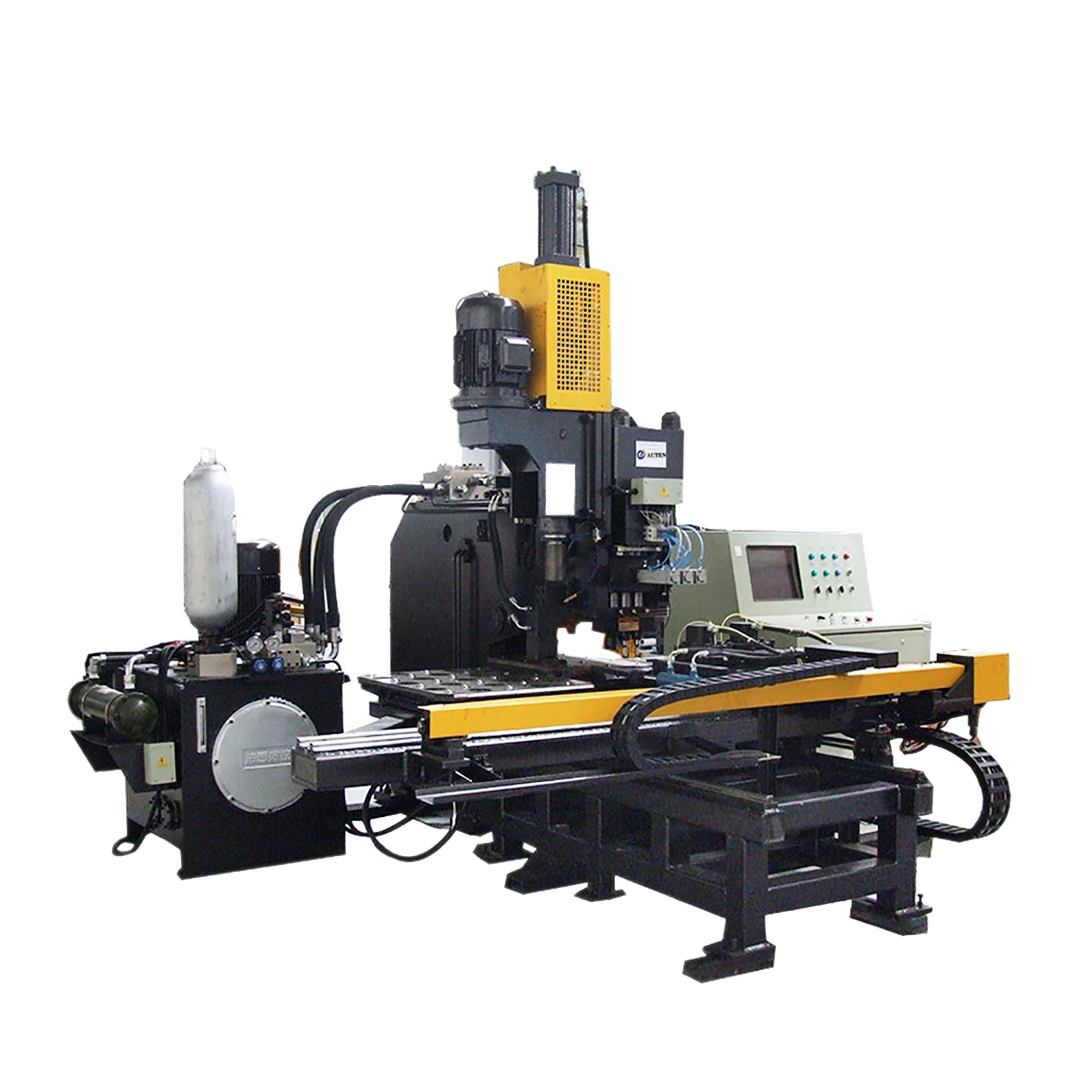

It is mainly used in steel structure drilling in construction, bridge, tower etc., and can be use din pipe and plate of boiler, petro line, baffle plate and round flange.

High Speed CNC Plate Drilling, Tapping and Milling Machine for Metal Plate, Flange and Tube Sheet

1. The bed, gantry and other large welding parts,After full heat aging treatment, high temperature annealing at 550 ℃ and holding temperature not less than 4 hours, can eliminate internal stress effectively,So dynamic and static rigidity is superb, deformation is very small.(We can produce the heat treatment report)

2. The drilling spindle is driven by a 15kW strong over-load special spindle variable frequency motor,It has high torque at low speed and can bear heavy cutting load. The drilling is strong and the drilling stability is good.

3. The CNC system use the Siemens 808D,with the corresponding Siemens servo motor and servo drive. It has good compatibility, powerful and very easy to operate.

4. Key transmission components such as linear roller guide, precision ball screw and other installation of high precision.For example, there is a installation base planeon linear guide, use the 0.04 mm feeler check after tightening,shall not be inserted;The tolerance of the parallelism between the linear guidesis 0.03 / 1000mm; ball screw and linear guide parallel to the tolerance 0.03 / 1000mm and so on.

Model | PZG2016 | PZG3016 | PZG4016 |

Max work piece size (L×W) | 2000X1600mm plate or Φ1600mm flange | 3000X1600mm plate or Φ1600mm flange | 4000X1600mm plate or Φ1600mm flange |

Max. thickness of work piece | 15~100mm (hydraulic clamp), 120mm (T-slot) | ||

Clamping type | Hydraulic clamp, T-slot | ||

Drill unit type | sliding table, servo control | ||

Drill head quantity | 1 | ||

Max drill diameter | Ф40/Ф50mm | ||

Taper hole of spindle | BT40/BT50 | ||

Spindle motor power | 22 kW | ||

Spindle speed | 30~3000r/min | ||

Servo motor power of X axis | 1.5 kW | ||

Servo motor power of Y axis | 1. 5 kW | ||

Servo motor power of Z axis | 3 kW | ||

CNC system | SIMENS 808D | ||

CNC axis quantity | 3 | ||

Position precision | ≤±0.08mm | ||

Repeated position precision | ≤±0.04mm | ||

Overall size | About 4.5x3.9x3.2m | About 5.5x3.9x3.2m | About 6.5x3.9x3.2m |

Weight | About 11 tons | About 12 tons | About 13.5 tons |

With function of CAD/CAM automatic generation | |||