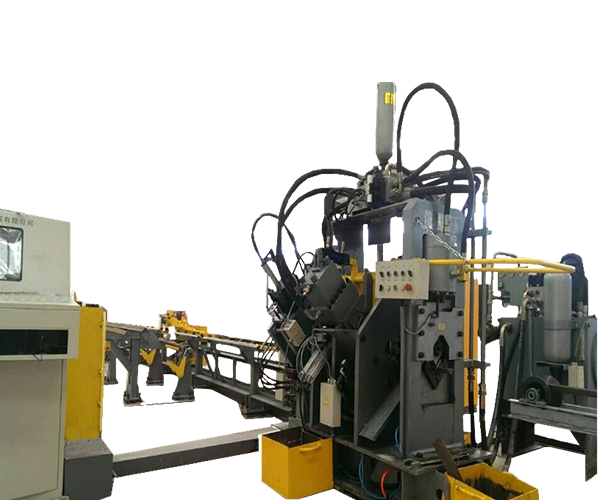

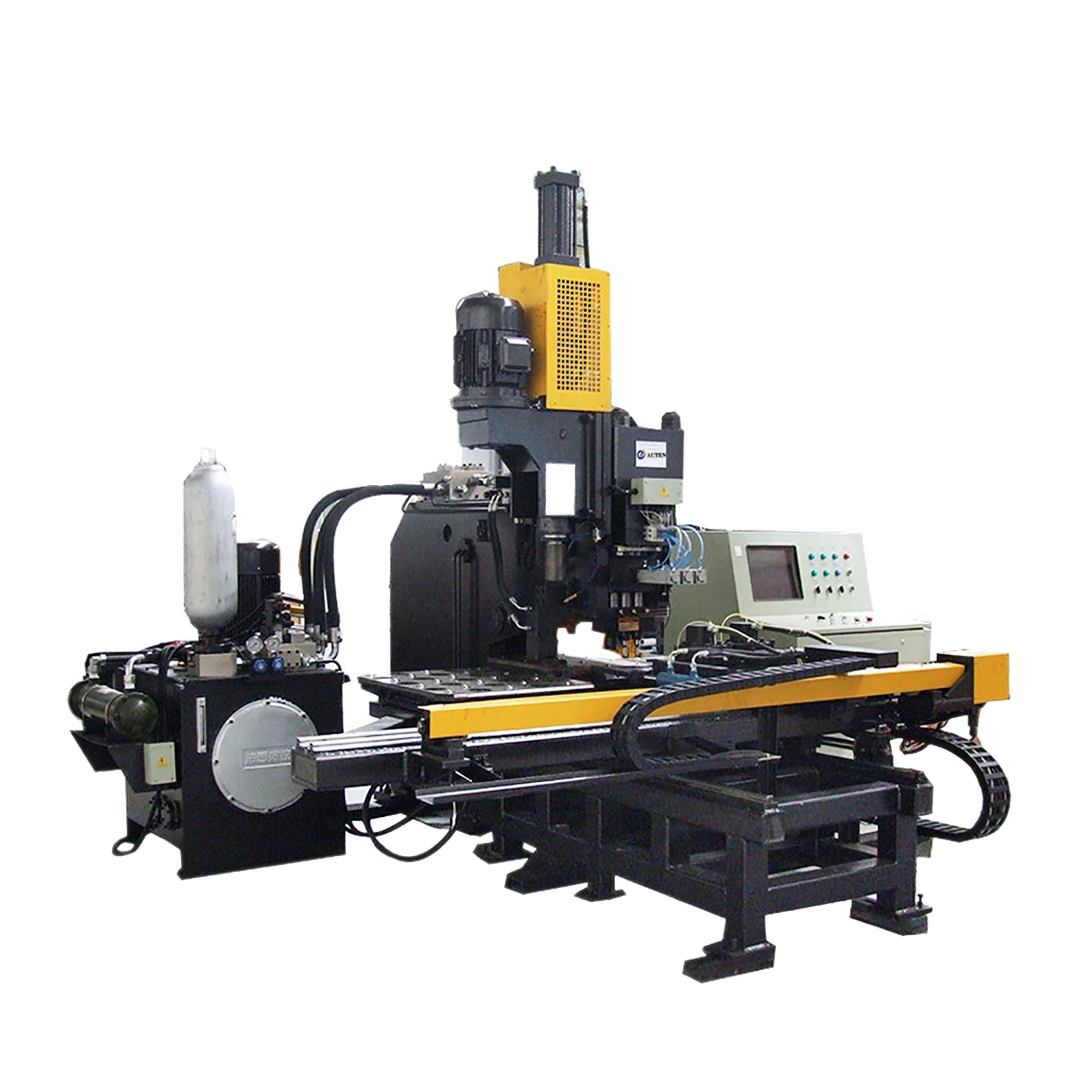

Used to drill holes on the metal plate in the fields of construction steel structure, bridge, tower manufacturing, etc.

CNC Plate Drilling Machine for Metal Plate and Flange

Introduction:

1. This machine aims to drilling holes on the metal plate of building steel structure, power iron tower and petrochemical equipments. It adopts gantry type structure. The axis X, Y and Z are drove by servo motor through precise ball guide screw. It positions automatically, precisely and quickly and finishes the processing of drilling automatically. Therefore, it highly improves the precision and speed. Meanwhile, it avoids repairing and scraping caused by manual position or drilling error.

2. The control system of this machine adopts host computer and PLC control system. The computer is installed with automatic programming software and machine monitoring software, which can convert the AUTOCAD graph file to processing program directly. It also very fast and easy, even programs it manually. The new operator without experiences of operating computer can program it in short time.

3. Automatic chip removal and circulation cooling system reduce the nonproductive time and labor intensity. The operator only need to load and unload work piece and change the drills.

4. The advanced CNC drilling power heads can automatically adjust to optimizing feeding speed and rotational speed through computer control according to different diameter of holes. It also can be adjusted manually according to different conditions. Besides to processing through-hole, it also can process blind holes, counter bore and so on. It has quick chuck device, which make the drills go up and down easily, conveniently and quickly. We also supply Morse 3#, 2# drilling reducing sleeves, which fit for below φ50mm twist drills.

5. This CNC drilling machine is designed according to the work piece features and precision requirements; it has compact form and is flexible, it meets the processing requirements better. No matter the holes are arranged as circle or straight line, it can finish the work quickly and accurately. Therefore, this machine is cost-effective choice.

Model | PZ2012 | PZ2016 | PZ3016 | ||

Max size of work piece(mm) | one piece | 2000×1000 | 2000×1600 | 3000×1600 | |

two piece | 1000×1000 | 1600×1000 | 1600×1500 | ||

four piece | 1000×500 | 800×500 | 1500×800 | ||

Max. thickness of work piece | 100mm, can overlap processing for thinner plates | ||||

Morse taper | #4 | ||||

Max. drilling diameter | Φ50mm | ||||

Drilling spindle | Rotating speed(rpm) | 120-560( Stepless speed adjustment) | |||

Max. feed stroke(mm) | 350 | ||||

Motor power(kW) | 5.5 | ||||

No. of champs | 12 | ||||

Motor power(kW) | Servo motors | X axis | 1.3 | ||

Y axis | 1.3 | ||||

Z axis | 0.85 | ||||

Weight(t) | About 5.3 | About 6.3 | About 7 | ||

Overall dimensions(L×W×H)(m) | About 4.5x2.2x2.8 | About 4.5x2.6x2.8 | About 5.5x2.6x2.8 | ||