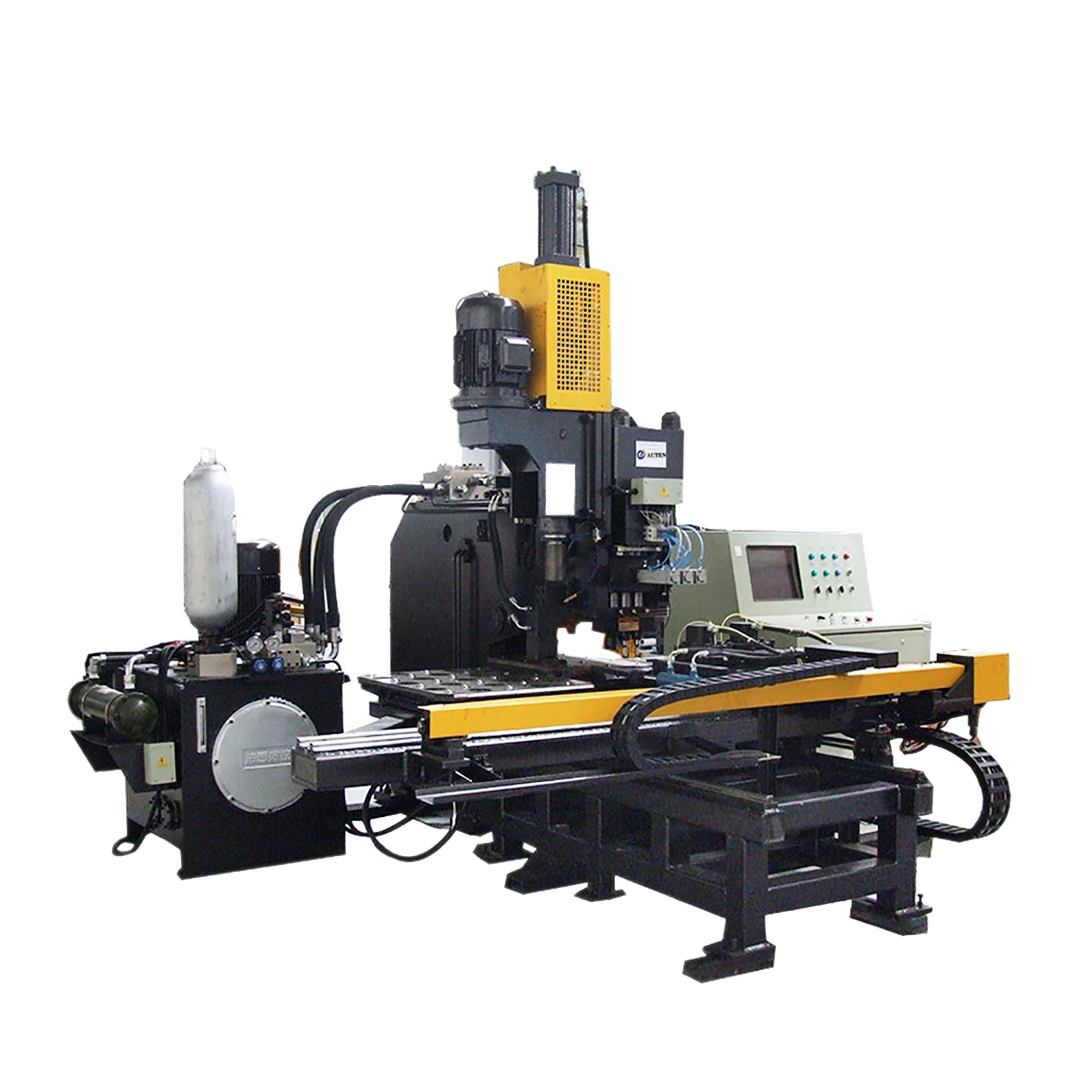

The internal cylindrical grinding machines are suitable for high-precision grinding of the internal cylinders with small-medium sized workpieces with a maximum length of 500mm.

High Precison CNC Internal Grinding Machine

■The internal cylindrical grinding machines are suitable for high-precision grinding of the internal cylinders with small-medium sized workpieces with a maximum length of 500mm.

■ The machine tools can be combined with various types of automatic loading and unloading systems or other customized processing systems.

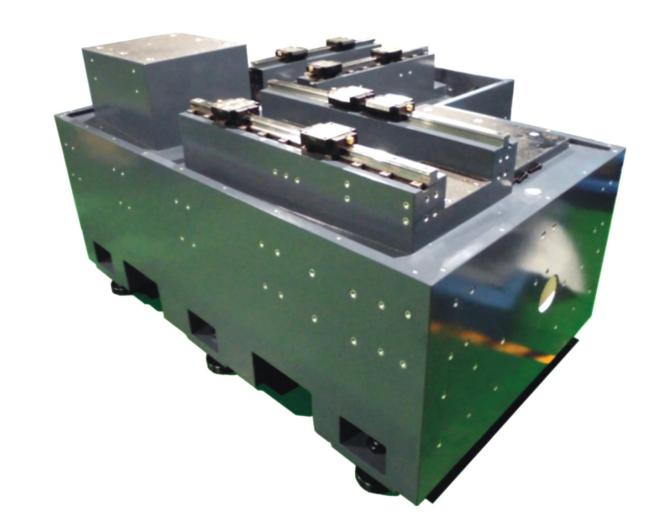

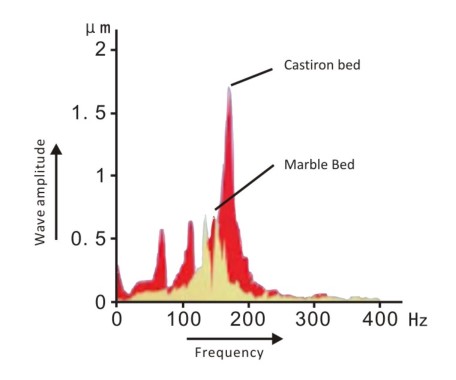

Marble bed

■The bed of whole series of products are all made of marble.

■There are the advantages such as good vibration absorption performance , intensive to cold and heat, strong integration performance , with stability, environmental protection and energy saving, and so on.

Test

▪High-precision on-line detector system is adopted

▪ The outer and inner diameter can be measured online simultaneously

▪ The workpiece that can be calibrated and measured

▪ Zero and reference points can be set for subsequent machining

▪ Reduce non-machining time during grinding

▪ Improve the accuracy of parts

System

▪ The most powerful CNC control unit

▪ The whole series of products adopt SIEMENS operating system

▪ SINUMERIK Brand-new SINUMERIK user operating interface

▪ Predetermine movement control to shorten processing time and improve the quality and accuracy of the workpiece surface

▪ It not only reduces the setup time and operation complexity of machine tools, but also makes it easy for operators to view and edit by equipping with a variety of grinding form procedure

▪ Ethernet, USB and flash card storage.

▪ The simplest interactive design, easy to learn, and large storage.

▪ Remote diagnosis and help, background editing function, setting a security password.

Spindle

▪ This spindle is a high-precision grinding spindle made in Switzerland, it is the best choice for the best process design, with the following best quality characteristics:

a. Short preheating time. Easy to operate, convenient maintenance and a wide range of applications

b. Good mechanical properties with durabilities

Grinding wheel repair system

High-precision motorized spindle-powered roller-type structural grinding wheel-repairing method, the best choice for high-precision and high-efficiency forming and dressing grinding, is mainly used for dressing internal and external cylindrical CBN grinding wheels, with characteristics of high dressing precision, high efficiency, good straightness, etc. The single point diamond pen dressing method can be chosen.

Lines of business

Workipieces:

Name | AT-N60 | AT-N120 | |

Working ability | Scope of grinding | φ2-φ60mm | φ5-φ120mm |

Max. grinding depth | 200mm | 360mm (to lengthen) | |

Chuck type | 6-8 hydraulic chuck (Match special tool ) | ||

Max. load | 25kg | 80kg | |

Working spindle table | Rotate speed | 0-1200rpm | |

Rotate angle | 12° | ||

Spindle motor | 3.5 kw | ||

X-axis | Feedback system | Closed-loop system | |

Strokemm | 300mm | 300mm/500mm | |

Max. moving speed | 100 m/min | ||

Min. feed | 0.001 (0.0001) | ||

Servo motor of X-axis | 3.5kw | ||

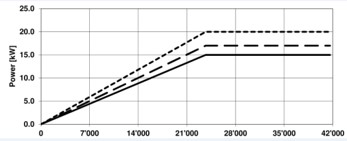

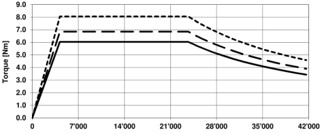

Z-axis | Spindle motor | 15kw | |

Rotate speed | 20000rpm/ 36000rpm/ 42000 rpm | ||

Strokemm | 100mm | 130mm | |

Z-axis drive | Servo motor 3.5kw | ||

Min. feed | |||

Cooling system | Equipment filter system | Magnetic separator + Paper filter machine | |

Tank volume | 100 L | ||

Motor | 0.2 KW | ||

Lubricating system | Tank volume | 2 L | |

Motor | 45 W | ||

Hydraulic system | Tank volume | 60L | |

Motor | 2.2KW | ||

Size/Weight | Equipment protection type | Total seal protection | |

Weight | 6000Kg | 6500Kg | |

Packing (L ×W ×H) | 2300×2000×2100(mm) | 3600 x 2300 x 2100 (mm) | |