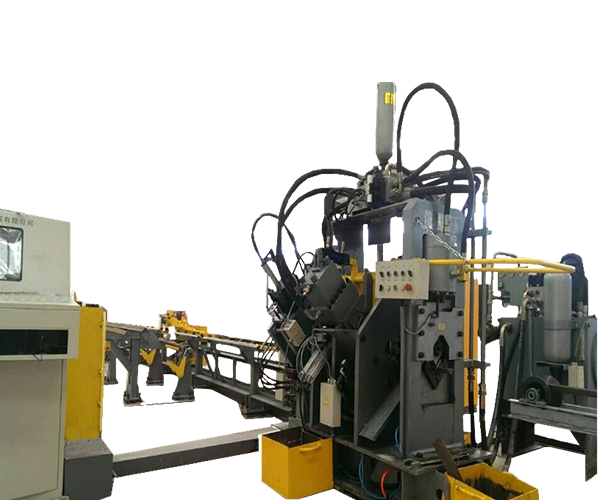

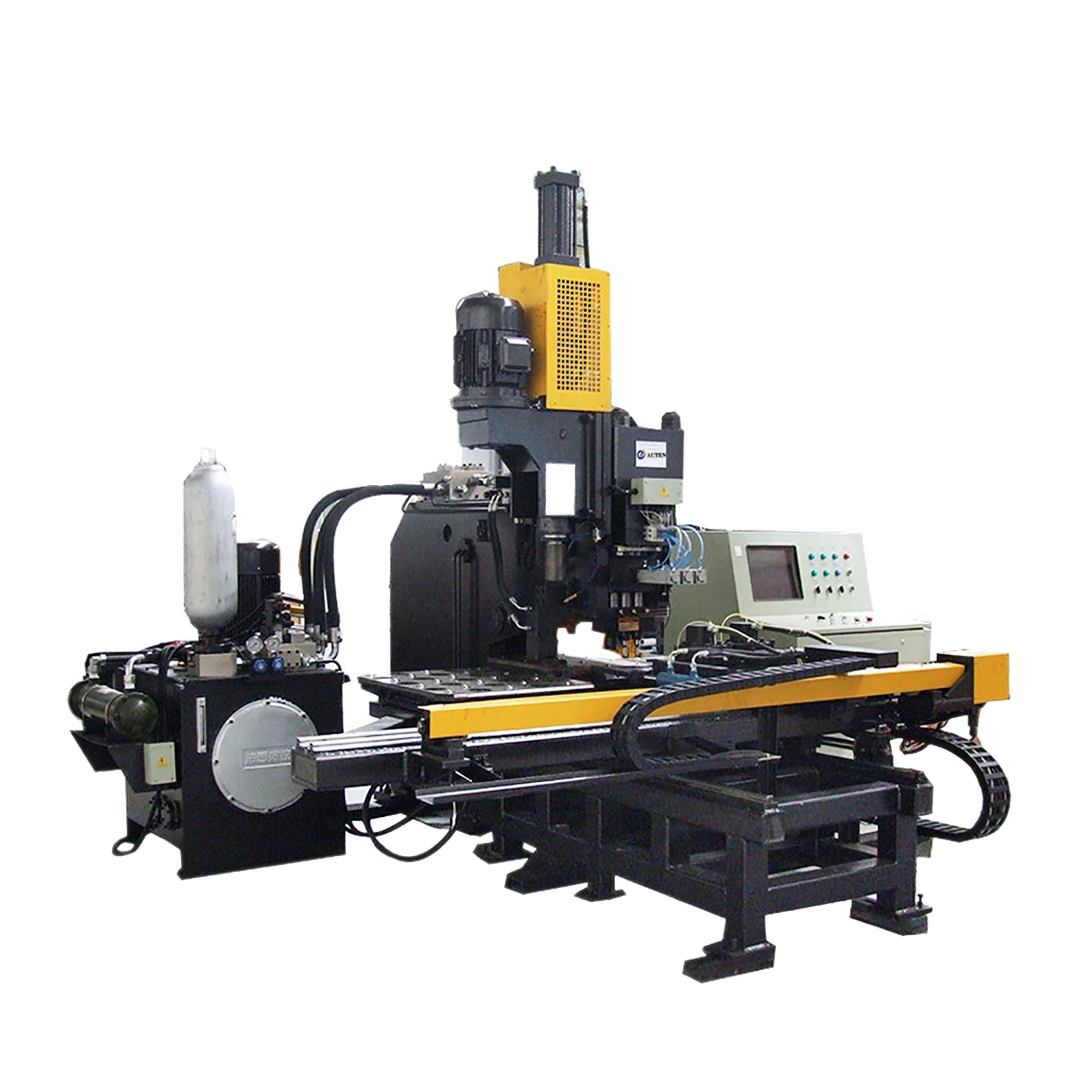

Automobile Truck Beam Punching Line

Automobile Longitudinal Beam CNC Punching Production Line Machine

It used for automobile flat plate longitudinal beam punching.

Inquiry now