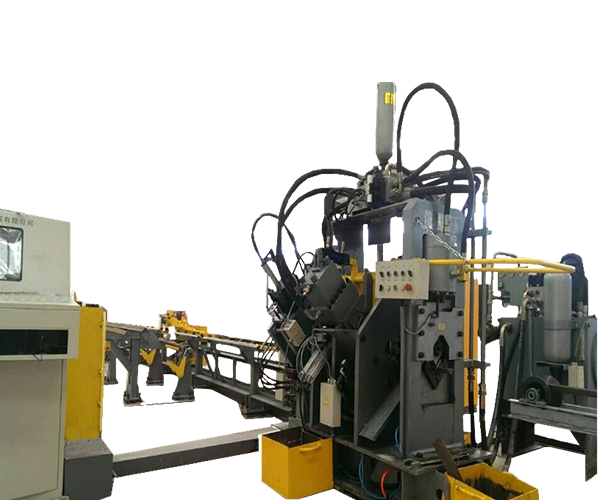

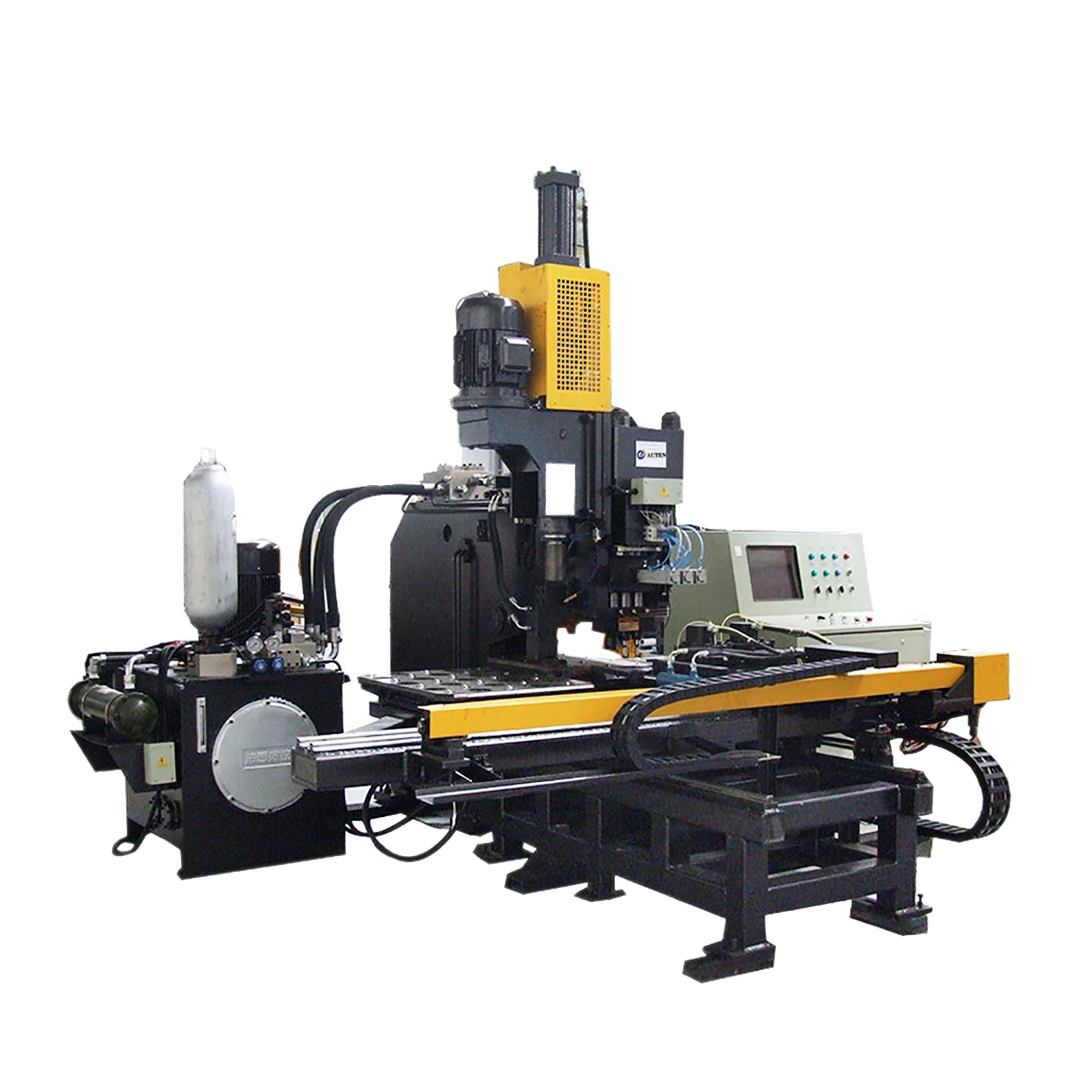

Compact design, small footprint and good rigidity make it an ideal grinding machine for high quality of application fields and production environments.

High Precision CNC External Grinding Machine

■Compact design, small footprint and good rigidity make it an ideal grinding machine for high quality of application fields and production environments.

■This kind of grinding wheel with the diameter of 600mm can be installed, which is the best choice for small batch and mass production.

■ The machine tools can be combined with a variety of automatic loading and unloading systems towards different client demands, such as robots, external or internal gantry structures, or other customized processing systems.

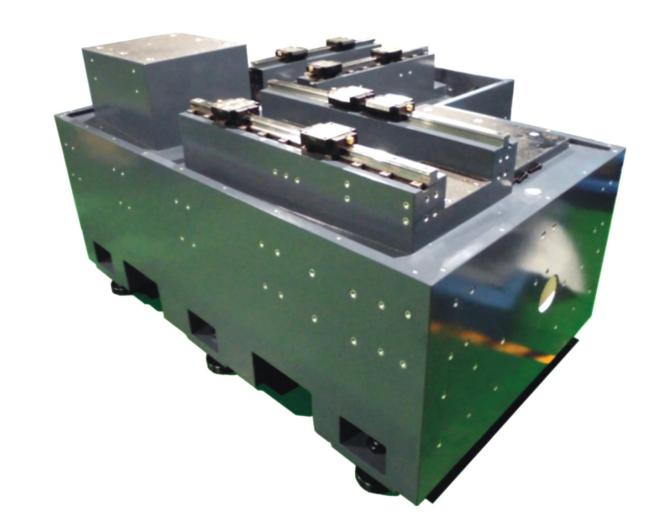

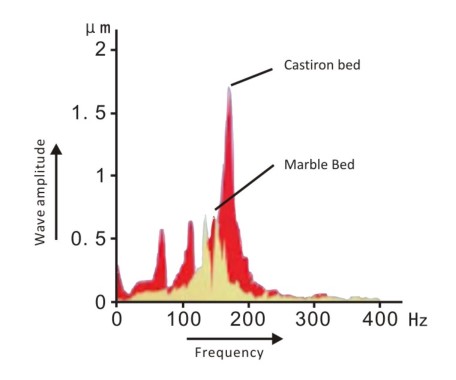

Marble bed

■The bed of whole series of products are all made of marble.

■There are the advantages such as good vibration absorption performance , intensive to cold and heat, strong integration performance , with stability, environmental protection and energy saving, and so on.

Test

▪High-precision on-line detector system is adopted

▪ The outer and inner diameter can be measured online simultaneously

▪ The workpiece that can be calibrated and measured

▪ Zero and reference points can be set for subsequent machining

▪ Reduce non-machining time during grinding

▪ Improve the accuracy of parts

System

▪ The most powerful CNC control unit

▪ The whole series of products adopt SIEMENS operating system

▪ SINUMERIK Brand-new SINUMERIK user operating interface

▪ Predetermine movement control to shorten processing time and improve the quality and accuracy of the workpiece surface

▪ It not only reduces the setup time and operation complexity of machine tools, but also makes it easy for operators to view and edit by equipping with a variety of grinding form procedure

▪ Ethernet, USB and flash card storage.

▪ The simplest interactive design, easy to learn, and large storage.

▪ Remote diagnosis and help, background editing function, setting a security password.

Spindle

▪ This spindle is a high-precision grinding spindle made in Switzerland, it is the best choice for the best process design, with the following best quality characteristics:

a. Short preheating time. Easy to operate, convenient maintenance and a wide range of applications

b. Good mechanical properties with durabilities

Grinding wheel repair system

High-precision motorized spindle-powered roller-type structural grinding wheel-repairing method, the best choice for high-precision and high-efficiency forming and dressing grinding, is mainly used for dressing internal and external cylindrical CBN grinding wheels, with characteristics of high dressing precision, high efficiency, good straightness, etc. The single point diamond pen dressing method can be chosen.

Lines of business

Workipieces:

Name | AT-80 | AT-300 | AT-400 | |

Capacity | Max. machining OD | φ80mm | φ300 mm | φ400 mm |

Center distance | 250mm | 650/1000/1500 (mm) | ||

Swing over bed | φ180mm | φ350mm | φ450mm | |

Max. load of center distance | 50Kg | 150/225/320 (Kg) | ||

Grinder Size | D×W×Aperture | φ600x30-50xφ203 (mm) | Φ600x50(100)xφ203(mm) | |

Rotate speed | 3000rpm | 4000rpm | ||

Speed and Travel | Max. feed speed | 10 | 20 | |

Feed stroke | 160mm | 320mm | 385mm | |

Min. unit feed | 0.001 (0.0001) min | |||

Spindle head | Rotate speed | 1000rpm | ||

Taper(Mohs) | 3 | 5 | ||

Spindle form | Centering/ simultaneously movement | |||

Through-hole aperture | φ26mm | φ38mm | ||

Tailstock | Sleeve stroke | 35mm | 60mm | |

Taper (Mohs) | 3 | 5 | ||

Worktable | Max. moving unit | 10m/min | 20m/min | |

Min. moving unit | 0.001 (0.0001) min | |||

Lubricating and Cooling | Grinding wheel spindle motor power | 25KW | ||

Oil pump motor output power | 2.2KW | |||

Lubevolume | 2L | |||

Cooling | 1/4 | |||

Machine | Weight | 6000Kg | 7000/7600/8200kg | 7200/7600/8500Kg |

Packing size(L×W×H) | 2800x1800x2000 (mm) | 3400x2200x2000 | 3800x2300x2000 (mm) | |