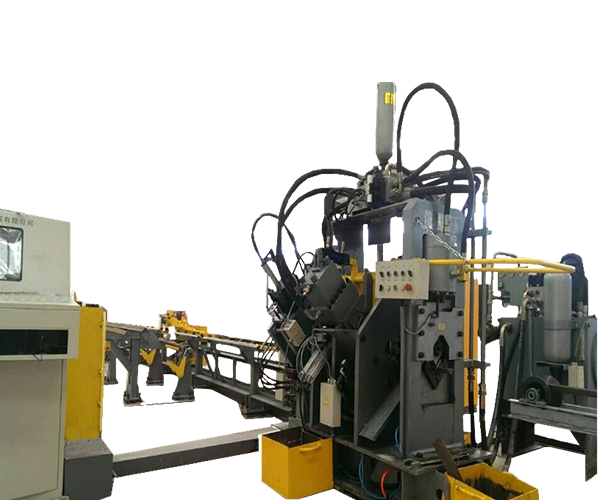

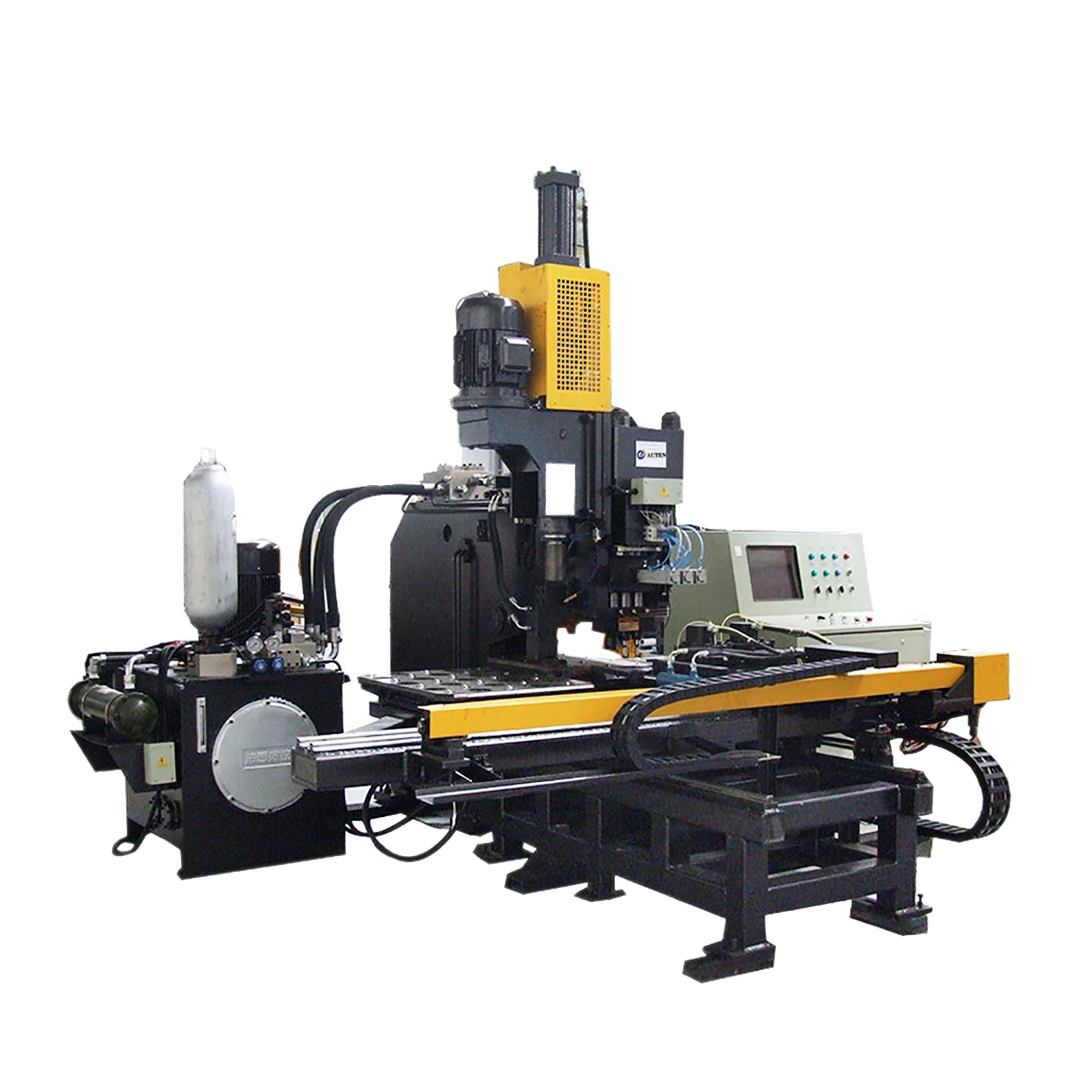

It is mainly used for the drilling of large welded H-beams, and can also be used for the drilling of rectangular and U-shaped steels. The holes on the three sides of the H-beam can be loaded and processed at one time, with high efficiency and high hole position accuracy. It is the key equipment for quality assurance in related manufacturing industries. The machining process of the machine tool is digitally controlled, and the operation is very convenient. It can realize automation, high precision and mass production.

1. The drilling efficiency of the equipment should meet the following basic requirements: the processing material is a low-alloy high-strength structural steel plate (Q345) with a thickness of 55mm and a hole diameter of φ32mm. One-time drilling is performed, and the time for uniaxial drilling of a single hole is less than 30 Seconds, the finish reaches 3.2-6.3.

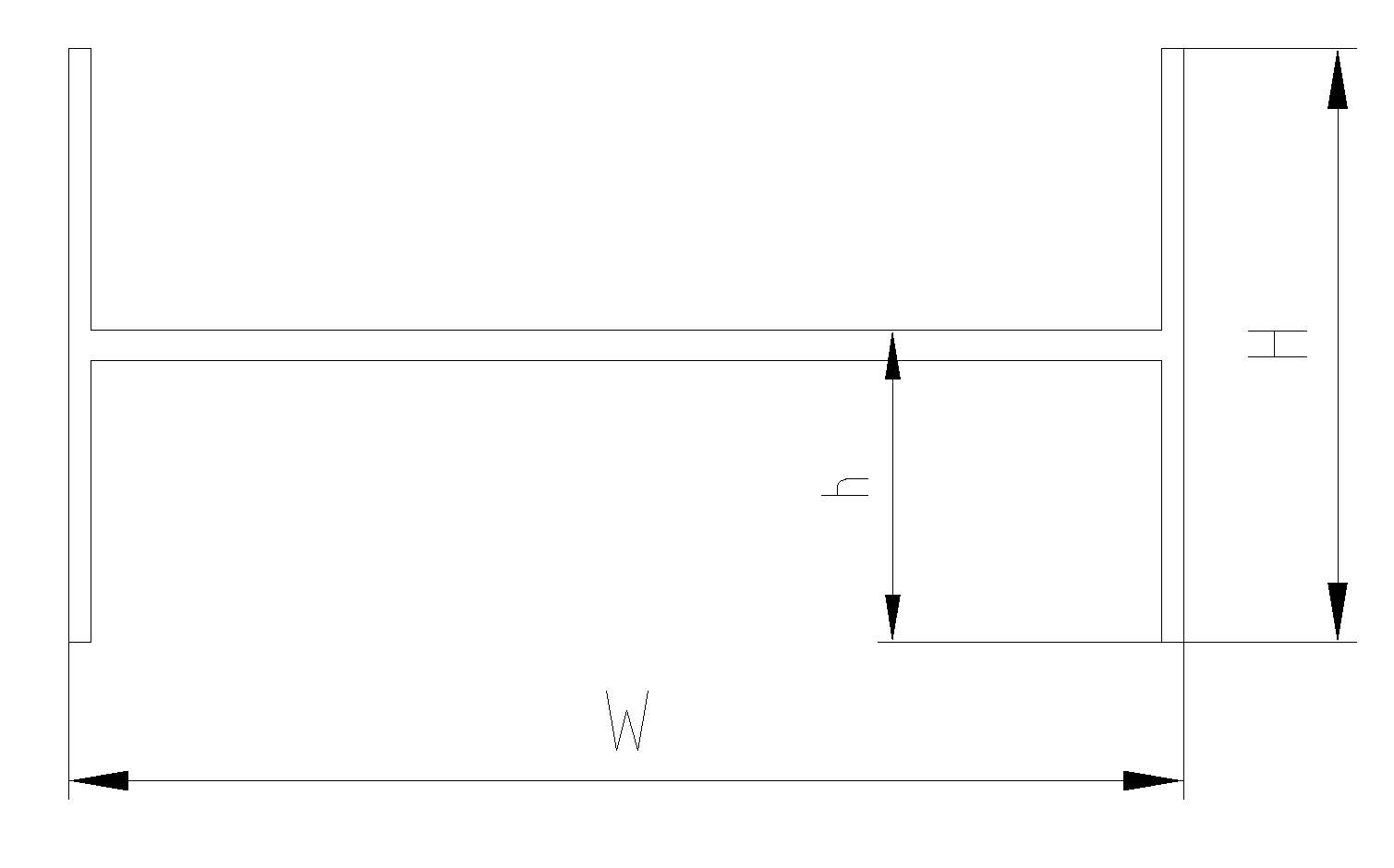

2. It has the function of detecting the three dimensions W, H and H as shown in the figure below, and automatically records and modifies these dimensions to compensate for welding errors and ensure the correct drilling position.

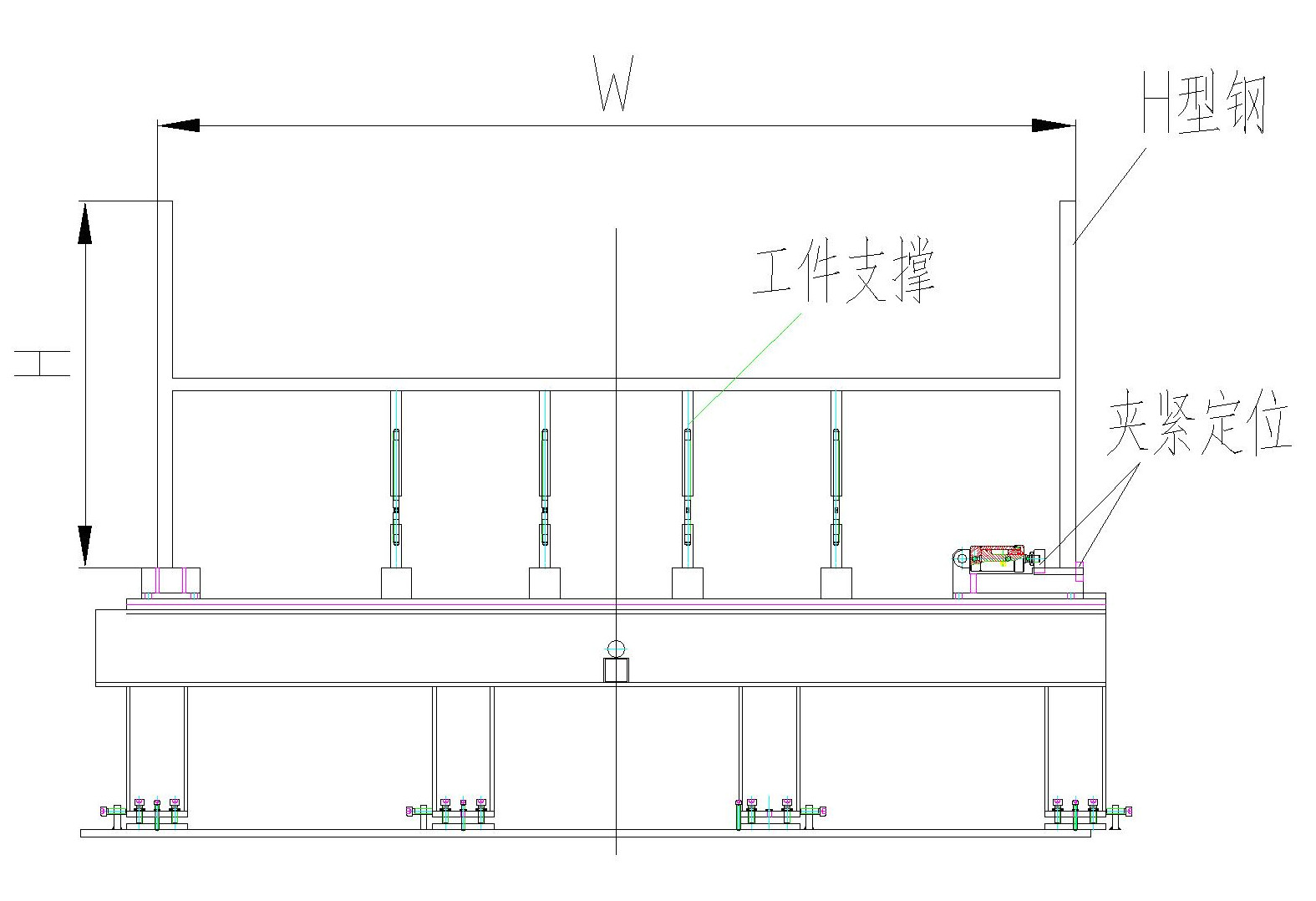

3. With flange plate positioning and clamping function, with web support function (to prevent excessive vibration of the web during high-speed drilling and damage to the tool). As shown below.

4. It has the function of spray cooling the tool in the center of the spindle, so as to use the inner cooling tool.

5. It has the functions of automatic broaching and hydraulic loosening.

6. Drilling programs compiled by other CNC equipment can be used on this CNC drilling machine as long as the format is in the general format.

7. Except for the chip conveyor, other parts of the equipment are installed above the ground.

Name | Unit | Parameter | |

Workpiece size | Section(width x Height) | mm | 400×600-3000×1250 |

Max. length | mm | 12000 | |

Max. thickness | mm | 60 | |

Max. Workpiece weight | t | 40 | |

Worktable | Size(LxWxH) | mm | 12500×2260*850 |

T-slot width and quantity | mm | 28,21 pcs | |

Web support | Qty. | 63 | |

Spindle | Type | BT40 | |

Qty. | 3 | ||

Max.rotating speed allowed | r/min | 0-8000 | |

Upper power head unit | Spindle type | BT40 of Precision high-speed spindle | |

Tool cooling method | Central spray inner cooling + liquid outer cooling | ||

Knife release method | hydraulic | ||

Servo motor power | kW | 15 | |

Spindle speed range | r/min | 0-3000 | |

Max. left and right stroke | mm | 2900 | |

Max.left and right movement speed | m/min | 10 | |

Max. up and down feed stroke | mm | 750 | |

Max. up and down feed speed | m/min | 6 | |

Distance from spindle nose to table | mm | 850-1600 | |