It used to punching holes on round pipe, square tube and profiled bar.

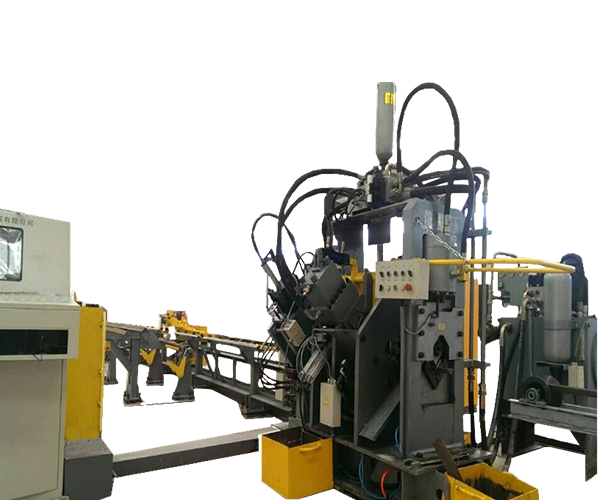

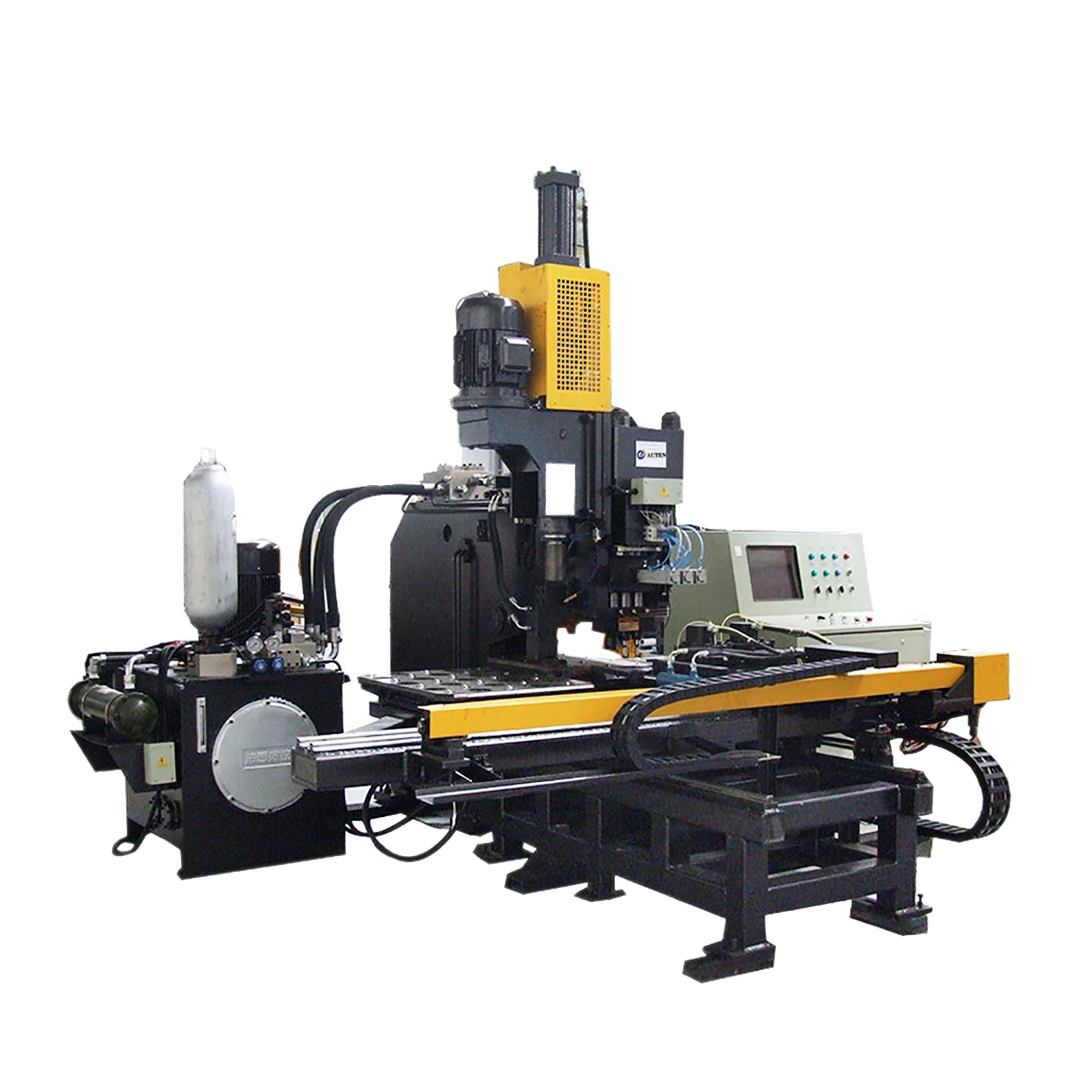

CNC Tube pipe punching Machine Line Model PM60B

★ TFT human-machine interface display, touch screen setting, the Numerical control system, and precise positioning servo motor, size of memory function in storage module.

★ Structure: By powerful composite combination, the frame of thick durable components.

★ Mould Exchange: Easy and simple, no need tool setting, prolong the working life of tools. Only need 3 minutes for changing tools.

★ The punch and dies are made by special process, the antifraying is 5~10 times than normal process.

★ Processing setiing: 1.single-punch; 2.double-punch; 3. non-equidistant punching; 4.punching equidistant,

★ With push rod function, the whole pipe can be completely punched.

★ Oil hydraulic and servo system

1.Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

2.Whenever the oil cylinder is moving downward, the machine is designed with hydraulicdifference driving loops rated at high or low RPM .It is also featured with high speed downward moving, low speed processing and hi-speed position resume .It is available to increase the formation stability of work pieces during puncturing .In addition to increasing the activation speed, it can effectively reduce HP lead to save electrical energy.

3.The electrical control system is designed with human machine interface 150mm(Stroke available for positioning) the moldset is designed with 750mm in depth available for forward and backward 150mm moving accessibility. Disatance adjustment adopts Position foot design, opening distance, slow speed position, lower limit position, easy operation with high precision.

4.Our machine is adopted with Japan-made serve motor driving devices and the feed-in and receiving speed can be set to high speed and high precision to enhance the productivity.

5.It is featured with sufficient clamping force of clamping oil cylinders and the position of workpieces is stable and uneasily loose off.

Max. Workpiece size | 130x130mm |

Φ150mm | |

Aperture and thickness | Φ50×τ4~Φ16×τ13 |

Max. Preocessing length | 6000mm |

Max. Punching force | 40t |

punching speed | about 1.5 seconds(guard bar can add two puch heads, can finish two holed per puching) |

Feeding speed | MAX:700mm/s (adjustment) |

Feeding precision | ±0.1mm |

System pressure | 16Mpa |

Oil pump displacement | 17-41ml/r(double pump) |

Motor power of oil pump | 11kw |

Servo motor power of feeding | 1kw |

Store program | 100 groups |

Overall dimensions | 8200mmx1450mmx2200mm |

Weight | About 5t(Processing capacity:6m) |