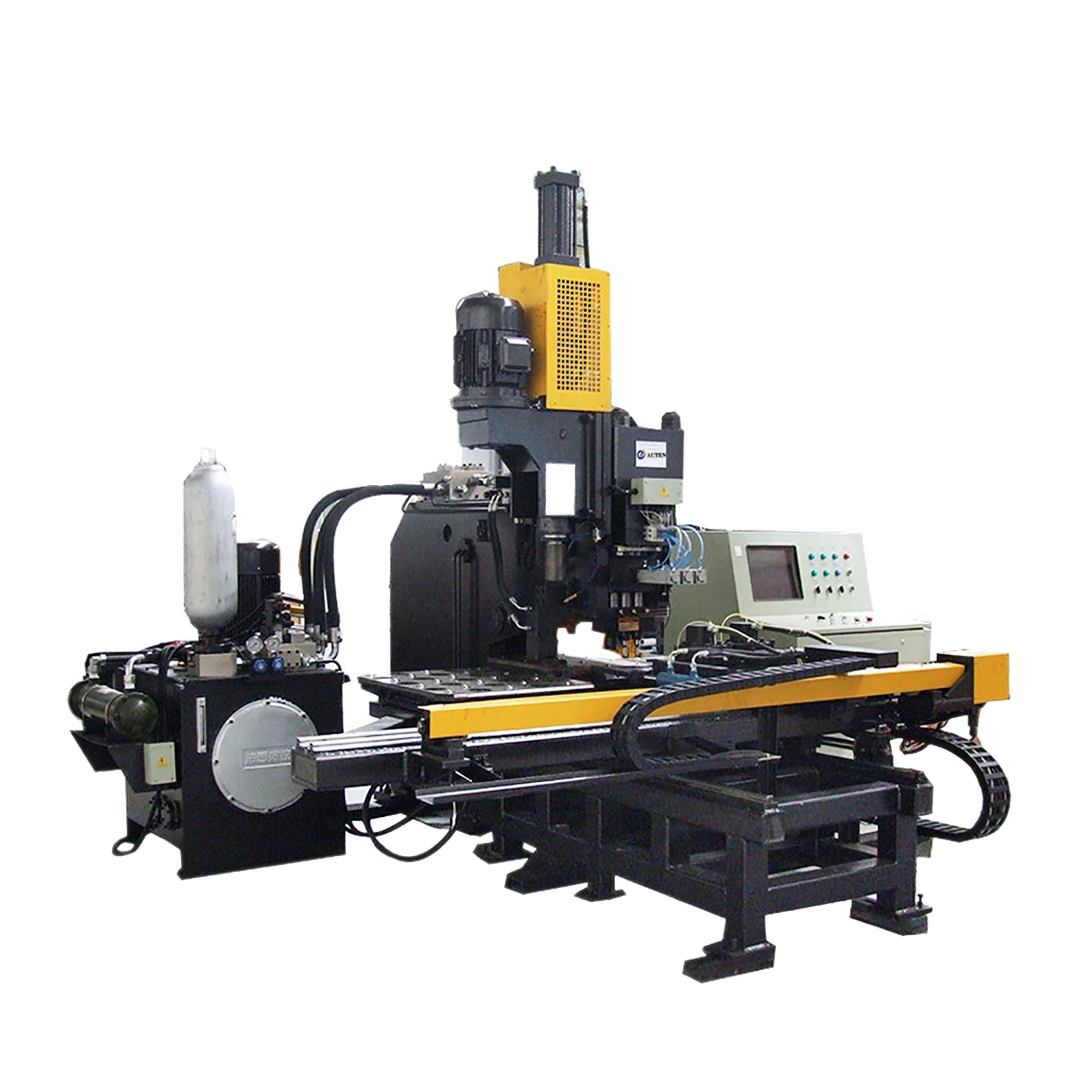

It is mainly used for drilling, tapping, marking and scoring H-shaped steel, channel steel, angle steel and other steels.

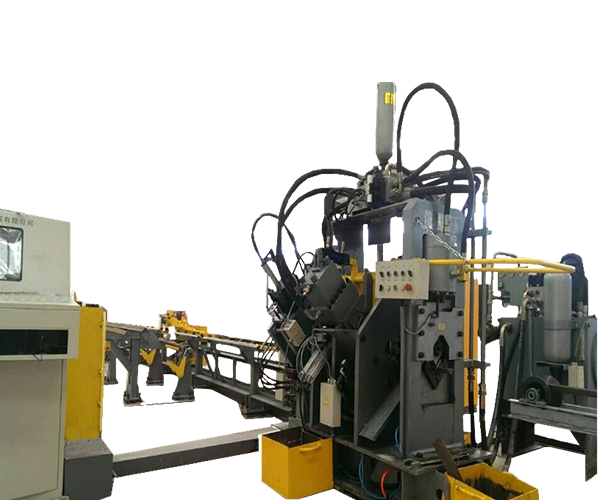

BHD Series CNC High Speed Drilling Machine for Beams

Product Features

1. Three BT40 high-speed spindles are used to drill the three faces of the H-beam.It adopts carbide drill bit, the spindle rotation speed can be up to 3000rpm. The processing efficiency is high and the drilling effect is good. The chips occurred during drilling will be conveyed by the chain-type chip conveyor.

2. The cooling system adopts mist cooling, which has the functions of internal cooling and external cooling. Each drilling spindle box is equipped with its own external cooling nozzle and internal cooling connector, which can be selected according to drilling needs. Internal cooling and external cooling can be used separately or simultaneously.

3. The automatic tool changer (ATC) system can be equipped according to the requirement of customers, no need to replace the tool manually, saving time and improving work efficiency.

4. The hydraulic disk marking machine can be equipped optionally. The disk is positioned via servo motor and can mark 36 different characters rapidly .

5. Automatic scribing and tapping functions replace traditional manual scribing. Scribing tools can be used to mark the plate positions for the next welding process on H-beam flanges and webs, saving time and effort while improving accuracy. Tapping can also be performed on H-beam flanges and webs, significantly improving production efficiency.

6. The work piece clamping during the feeding and processing, the longitudinal lifting of the clamp and the lateral push clamping, clamp fixing and loosening are all completed by the hydraulic system, which ensures the reliability of the equipment during operation.