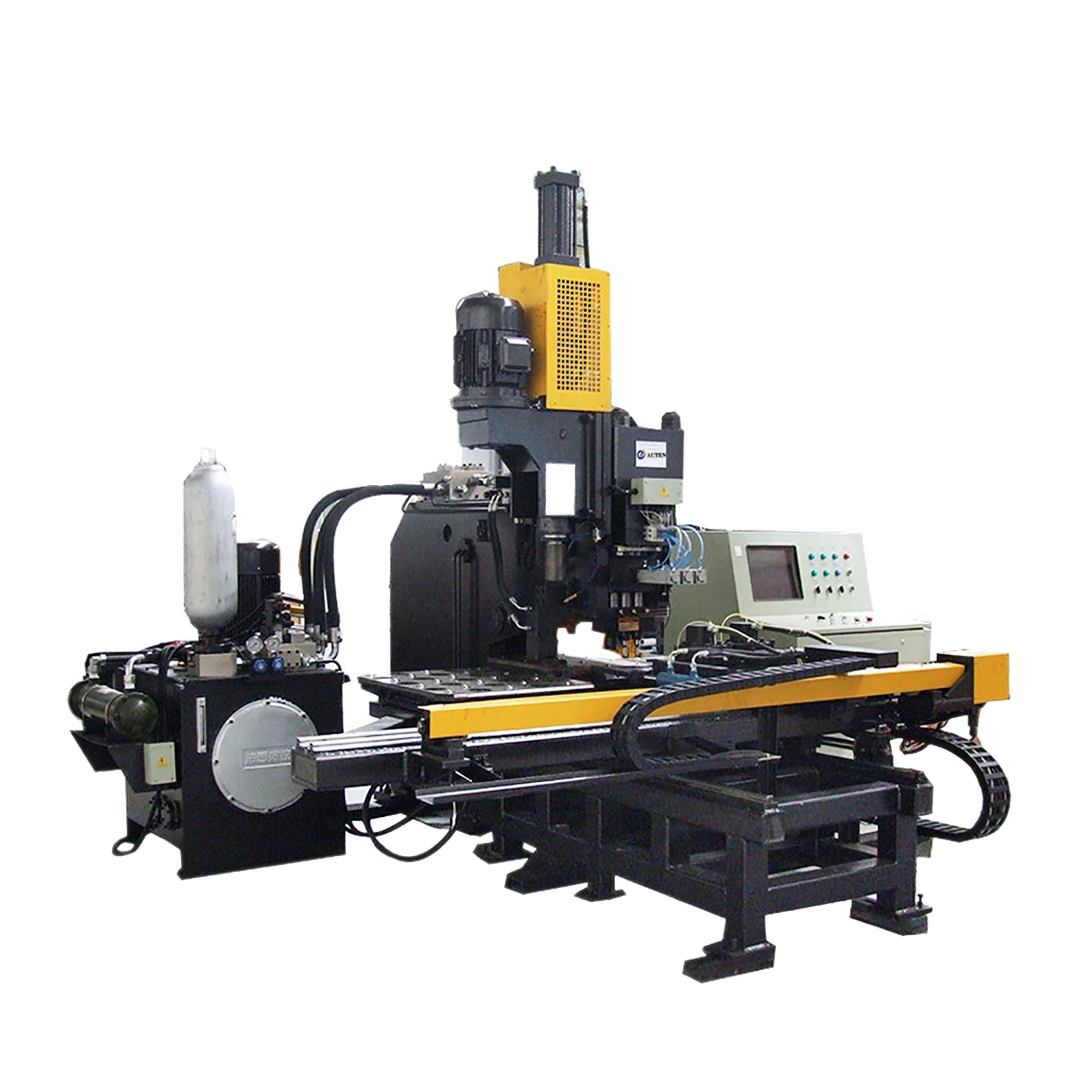

CNC Internal and External Circular Composite Grinding Machine High Precision

Application:

High-precision composite grinding machines are used for simultaneous grinding of external cylinders or tapered face, end face and internal cylinders, and are suitable for single-piece manufacturing and mass production.

Specifications:

Model | AT-60 | |

Capability | Φ20~φ60x40mm( to φ120mm maximum) | |

Max. grinding diameter | Φ35~φ140mm | |

Max. grinding length | 100mm(matching to 250mm) | |

Max. diameter of spindle | 350mm | |

Max. weight of workpiece | ||

Grinding wheel spindle form | Independent design for inner and outer diameter | |

Workpiece Spindle | Chuck form | Pneumatic / hydraulic |

Rotate speed | 1000rpm | |

Servo motor output power | 3.2KW | |

Internal Spindle | Rotate speed | 20000rpm/36000rpm42000rpm |

Max. strokemm of X-axis | 310mm | |

Max. strokemm of Z1-axis | 100mm | |

Motor output power of X-axis | 3.5KW | |

Motor output power of Z1-axis | 3.5KW | |

Specification of grinding wheel | Acc. to inner diameter | |

Max. moving speed | 10m/min | |

Min. feed | 0.0001mm | |

Motor power | 15KW | |

External Spindle | Rotate rate | 3000rpm/12000rpm (acc. To products) |

Max. range of Y-axis | 210mm | |

Max. range of Z2-axis | 200mm | |

Motor output power of Y-axis | 3.5KW | |

Motor output power of Z2-axis | 3.5KW | |

Specification of grinding wheel | 400 mm×30mm×203mm / 150 mm×30mm×203mm | |

Max. moving speed | 10m/min | |

Min. feed | 0.0001mm | |

Adjustable angle | 0~12° | |

Lubricating | Fuel tank volume | 2L |

Pump motor output power | 0.8KW | |

Cooling | Filter tank volume | 100L |

Pump motor output power | 0.075KW | |

Hydraulic System | Fuel Tank volume | 60L |

Output power | 2.2KW | |

Outlook | Size(L×W×H) | 2100mm*2500mm*2000mm |

Weight | 7500Kg |