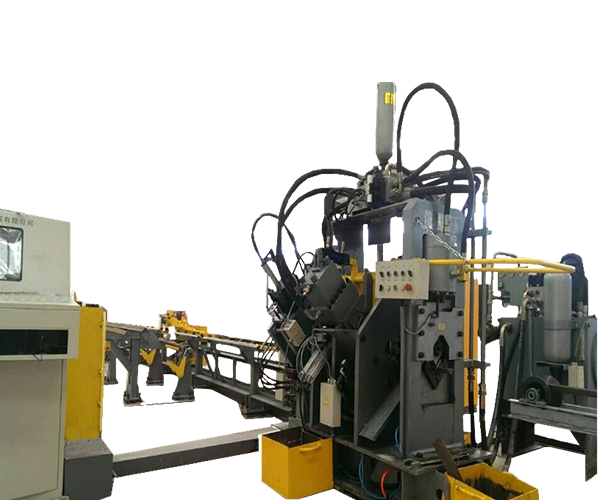

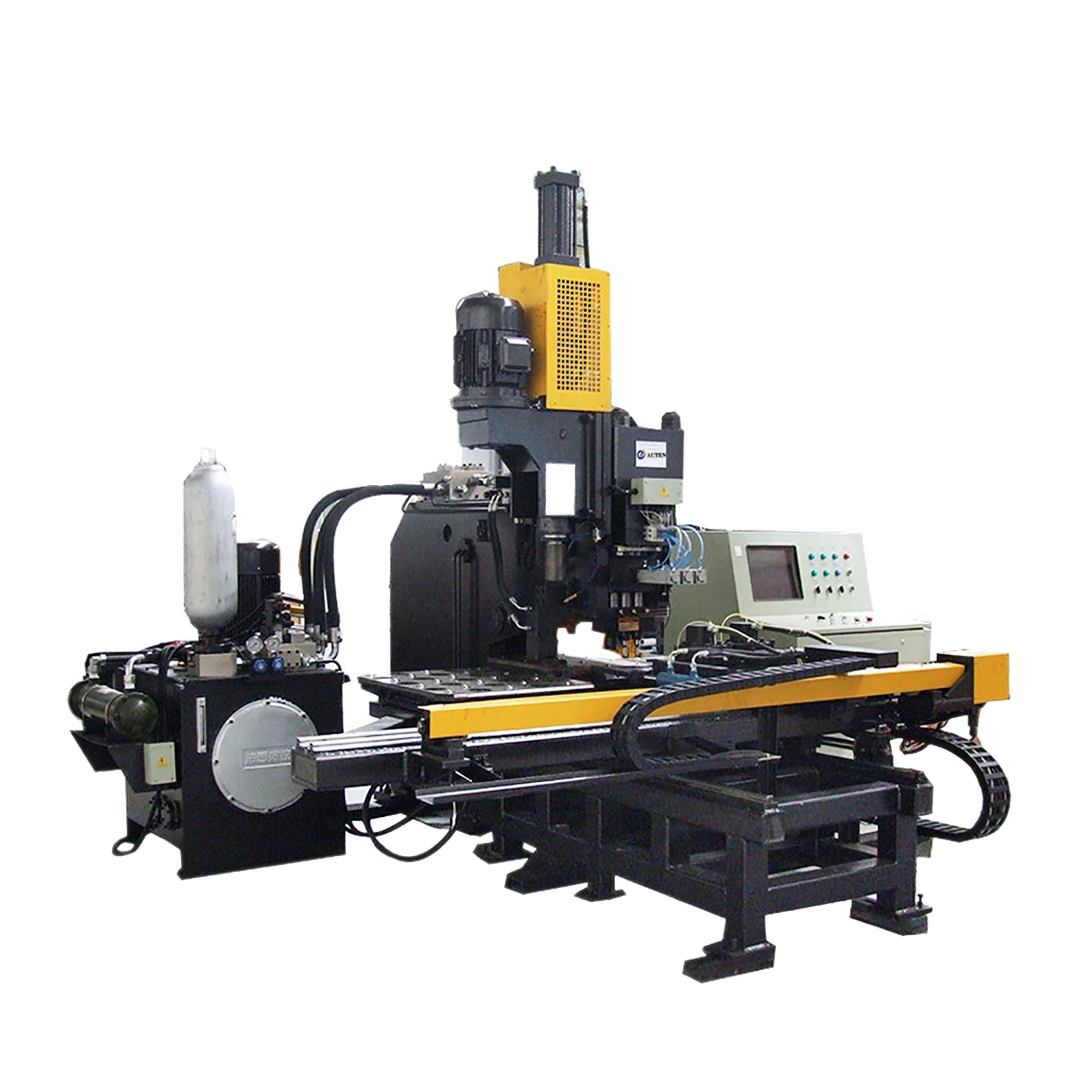

Automobile Truck Beam Punching Line

Truck beam stringer plate CNC punching production line Model FPCP120

It is a complete production line for automobile flat longitudinal beam punching. According to the punching needs of various car frames at home and abroad, and integrates various product advantages. developed products. This production line can perfectly meet the flexible processing requirements of various frame longitudinal beams, and has the characteristics of stability and high efficiency.

PREVIOUS

Inquiry now