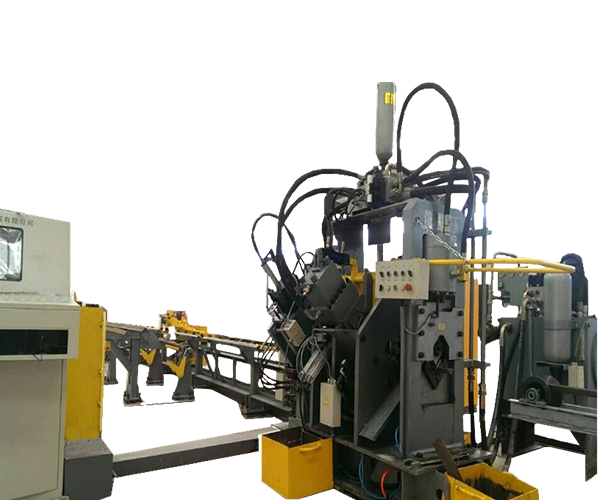

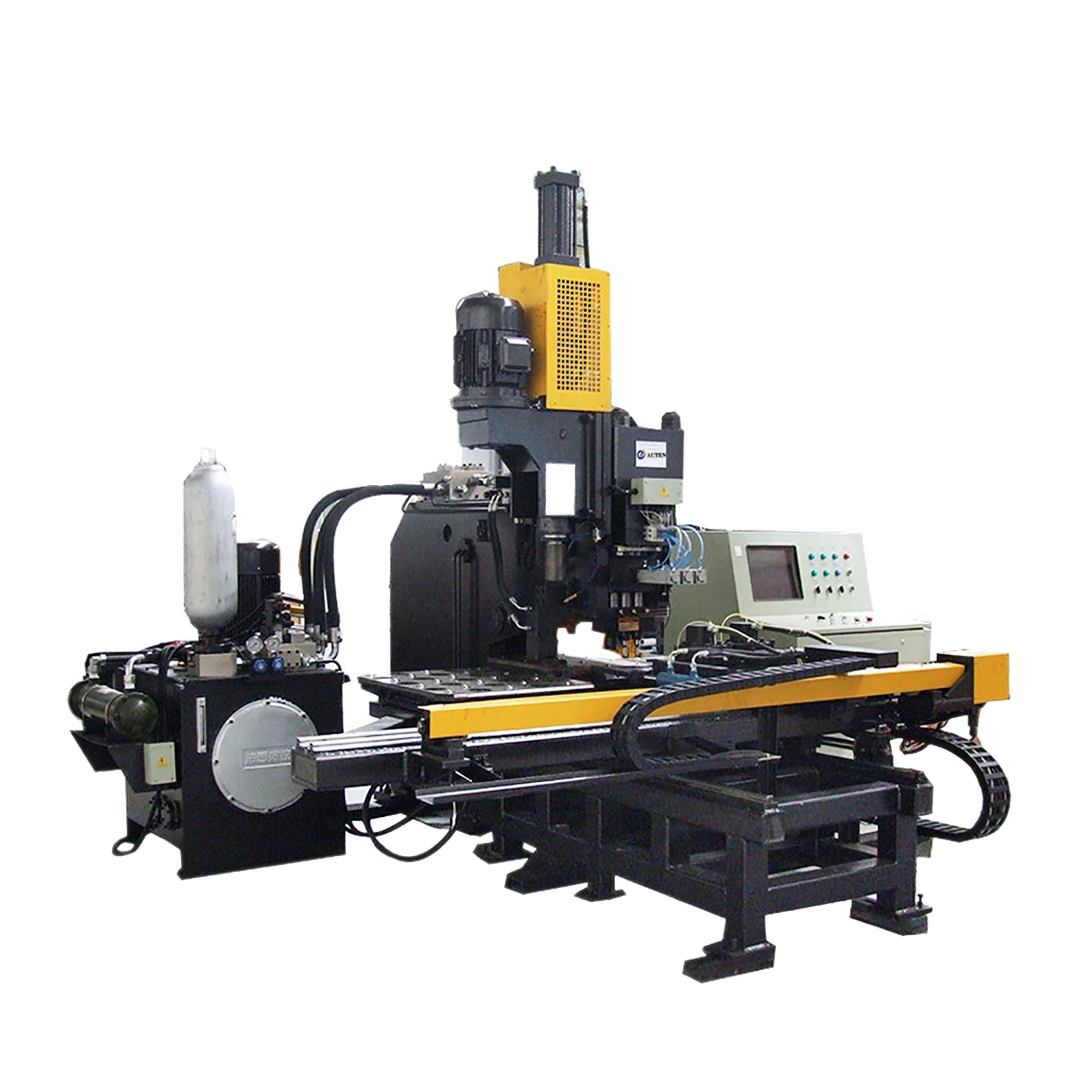

Used to shearing metal plates. Steel plate cutting machine.

* The main fram id fitted with numeric-control system special for shearing machines.

* The position of rear stopper is displayed in a real-time manner.

* Multi-step programmimg function is available and the rear stopper is able for automatic operation and continuos positioning to achieve an automatic adjustment for position of rear stopper.

* It is provided with counting function for shearing, to display the shearing numbers in a real time manner, able for power-failure memory of position of rear stopper, procedures, and paramerers.

* Imported ball bearing lead screw and linear guide rail are used, to ensure the positioning precision, so that the processing precision of machine is higer.

* Steel plate weded strusture, hydraulic transmission, nitrogen cylinder return;

* Easy to operate, reliable performance and aesthtic apperance;

* Blade gap adjustment instructions are signs, adjus in the light quickly;

* Lighting device, with ligths on the line and the stepless adjustment turret itinerary;

* Workspace mining area fence protect the personal safety device;

* After the block size and the shear numbe of digital display devices.

Specification | Shearing Thickness (mm) | Shearing Width (mm) | Shearing Angler ( ° ) | Number of Stroke (time/min) | Back gauge Rang (mm) | Motor Power (kw) |

QC11Y-6*2500 | 6 | 2500 | 30'--1°30’ | 16--35 | 20--600 | 7.5 |

QC11Y-6*3200 | 6 | 3200 | 30'--1°30’ | 14--35 | 20--600 | 7.5 |

QC11Y-6*4000 | 6 | 4000 | 30'--1°30’ | 10--30 | 20--600 | 7.5 |

QC11Y-6*5000 | 6 | 5000 | 30'--1°30’ | 10--30 | 20--800 | 11 |

QC11Y-8*2500 | 8 | 2500 | 30'--2° | 14--30 | 20--600 | 11 |

QC11Y-8*3200 | 8 | 3200 | 30'--2° | 12--30 | 20--600 | 11 |

QC11Y-8*4000 | 8 | 4000 | 30'--2° | 10--25 | 20--600 | 11 |

QC11Y-8*5000 | 8 | 5000 | 30'--2° | 10--25 | 20--800 | 15 |

QC11Y-12*2500 | 12 | 2500 | 30'--2° | 12--25 | 20--800 | 15 |

QC11Y-12*3200 | 12 | 3200 | 30'--2° | 12--25 | 20--800 | 15 |

QC11Y-12*4000 | 12 | 4000 | 30'--2° | 8--20 | 20--800 | 15 |

QC11Y-12*6000 | 12 | 6000 | 30'--2° | 6--20 | 20--1000 | 30 |

QC11Y-16*2500 | 16 | 2500 | 30'--1°30’ | 12--20 | 20--800 | 22 |

QC11Y-16*3200 | 16 | 3200 | 30'--1°30’ | 12--20 | 20--800 | 22 |

QC11Y-16*4000 | 16 | 4000 | 30'--1°30’ | 8--15 | 20--800 | 22 |

QC11Y-20*2500 | 20 | 2500 | 30'--3° | 10--20 | 20--800 | 30 |

QC11Y-20*3200 | 20 | 3200 | 30'--3° | 10--20 | 20--800 | 30 |

QC11Y-20*4000 | 20 | 4000 | 30'--3° | 8--15 | 20--800 | 30 |

QC11Y-25*2500 | 25 | 2500 | 30'--1°30’ | 8--15 | 20--800 | 37 |

QC11Y-25*3200 | 25 | 3200 | 30'--1°30’ | 8--15 | 20--800 | 37 |

QC11Y-25*4000 | 25 | 4000 | 30'--1°30’ | 6--12 | 20--1000 | 37 |

QC11Y-32*2500 | 32 | 2500 | 30'--4° | 6--12 | 20--1000 | 55 |

QC11Y-32*3200 | 32 | 3200 | 30'--4° | 8--12 | 20--1000 | 55 |

QC11Y-40*2500 | 40 | 2500 | 30'--4° | 4--10 | 20--1000 | 55 |