Used for cutting corner of angles and also used for punching & marking by installing of mould.

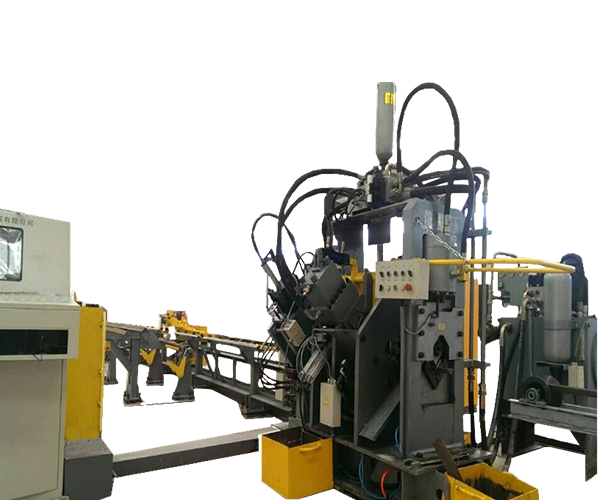

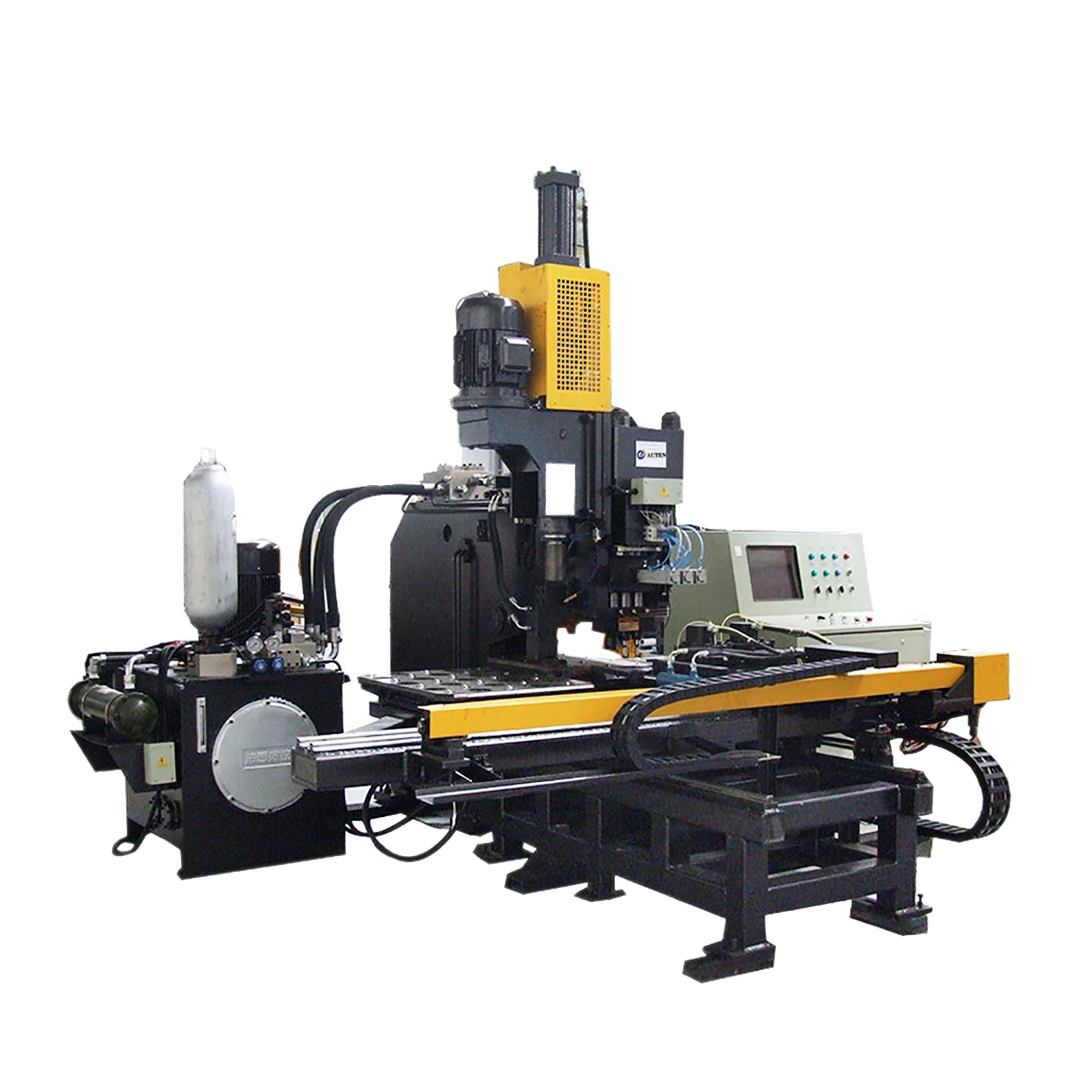

Hydraulic Angle Notching Machine for Angle Steel Tower

Applicable industry:

Used for cutting corner of angles and also used for punching & marking by installing of mould.

■The machine with opening C-type structure, its cutting mould is rectangular double-blade mode. Multi-directions rotational corner cutting mould can cut out different angle of angles only need to adjust rotation die-carrier so as not to rotate the angles, so corner cutting with little error only need small working area.

■The machine can be installed marking & punching system by customers’ request, that is, only need to exchange moulds so as to carry out marking or punching of angles.

■The machine with light adjuster makes corner cutting of angles accurately and easy to use it.

Model | QJ140 | QJ160 | QJ200(Four column) |

Functions | Used for cutting corner of angles in steel tower industry | ||

Nominal pressure(kN) | 800 | 1000 | 1600 |

Stroke of oil cylinder(mm) | 50 | 50 | 50 |

Times of stroke(min-1) | 20~25 | 20~25 | 20~25 |

Power of motor(kW) | 15 | 15 | 22 |

Throat depth(mm) | 325 | 325 | Column without throat |

Scope of angles(mm) | L40×40×3~ | L40×40×3~ | L40×40×3~ |

Rotary angles of corner cutting mould | 360° manual | ||

Overall dimensions of corner cutting mould(mm) | 650×650×500 | 700×700×500 | 830×700×600 |

Overall dimensions L×W×H(mm) | 1270×1020×1800 | 1300×1020×1880 | 1370×1120×1900 |